New study demonstrates CH-Bioforce lignins as promising building blocks for pressure-sensitive adhesives

A new peer-reviewed study has explored how lignins produced with CH-Bioforce’s BIOFORSENSE® technology can be transformed into soft, functional materials for pressure-sensitive adhesives (PSA). These adhesives are widely used in everyday products such as sticky notes, labels, tapes and the well-known Blu Tack®.

The research investigated lignins from birch, spruce and wheat straw, all produced with the CH-Bioforce process, and evaluated how they perform when grafted with poly(n-butyl acrylate) (PnBA). The work highlights how bio-based lignin can replace fossil-based polymers in entirely new adhesive applications.

Modified lignins successfully grafted with polyacrylate

The researchers first prepared lignin-based macroinitiators and then grafted them with PnBA using ATRP polymerisation.

The study confirmed:

- Successful lignin–polyacrylate grafting, verified through FTIR, NMR and SEC/GPC

- Clear differences between hardwood, softwood and straw lignins in macroinitiator formation and polymerisation efficiency

- Birch and spruce lignins showed the most effective copolymerisation behaviour, while wheat straw lignin displayed lower reactivity due to structural complexity

Gel permeation chromatography further demonstrated clear molecular-weight shifts, distinguishing true copolymers from simple blends.

Thermal and rheological properties support adhesive performance

The resulting lignin-g-PnBA copolymers displayed:

- Increased glass-transition temperatures compared to pure polyacrylate

- Structural differences between lignin sources reflected in their thermal decomposition profiles

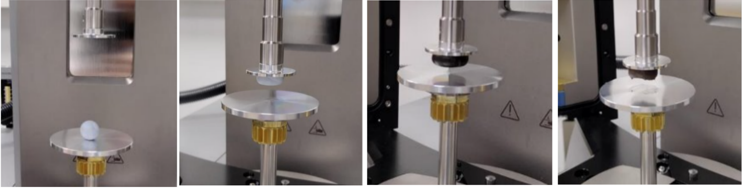

- Strong viscoelastic behaviour, with birch-based copolymers showing particularly good performance in rheology tests

- Compliance with the Dahlquist criterion, the established requirement for pressure-sensitive adhesives (low modulus under deformation)

Notably, birch-lignin-based materials (BLNBA2 and BLNBA4) showed adhesive behaviour comparable to commercial Blu Tack®, confirming excellent tack and softness in real-world use.

Lignin as a renewable route to soft, functional adhesive materials

This study provides strong evidence that CH-Bioforce lignins can be converted into soft, elastic materials suitable for PSA applications.

Unlike conventional petroleum-based polymers, lignin offers:

- Rapid renewability

- A high-value outlet for side streams

- The potential to reduce fossil-based content in consumer products

- Compatibility with circular economy principles

By demonstrating high-performing, lignin-based PSA materials, the research opens the door to sustainable alternatives for everyday adhesive products.

Want to know more? Read the whole article here!

CH-Bioforce Oy

CH-Bioforce Oy is a Finnish start-up founded in 2016. The company’s innovative fractionation technology dates back to 2011, when inventors Lari Vähäsalo, Nicholas Lax and Sebastian von Schoultz made their first findings. Today, the company forms part of the Chemec group, which operates in the chemical industry. CH-Bioforce currently employs ten members of staff. Our R&D and pilot plant is located in Raisio, Finland.